- English

- Français

- Tiếng Việt

The vault

The Woodless Construction vault - derived from Nubian vaults

Woodless Construction vaults are built without any supporting shuttering.

The basic vault form is very similar to that of an inverted catenary, the form taken by a chain suspended from its two ends, and thus, for the chain, a shape in pure tension. Since mud bricks are strong in compression and very weak in tension, it is important that the vault’s shape keeps the forces in compression. Inverting the form of the centenary provides this form, and the traditional Nubian vault respected this shape closely. The spanish architect Antonio Gaudi used the same roof form and principles.

In Woodless Construction, this catenary shape has been slightly modified to take account of extra loading over the sides of the vault. Tis revised shape is very easy for the novice builder to draw with the help of wires or string. Each vault is built up in a series of vertical courses that incline towards an end supporting-wall. The shape of the vault, the inclination of the courses, and the stickiness of the mud mortar, combine to keep the bricks in place during construction without shuttering.

To start, the vault shape is traced with strings or wire onto the end supporting-wall. In Woodless Construction, to facilitate keeping the vault alignment straight, the traditional practice of working from one end of the vault was changed to building vaults from both ends of the room being covered, so that guide strings could be stretched from one end wall to the other. In building the vault, it is important that the outward thrust onto each supporting wall is contained and transferred to the ground. This is achieved by making the supporting wall thick enough and by setting the vault ‘spring point’ low enough, or by providing a counter-thrust in the form of an adjacent roof. Understanding and compensating for the effect of the vault’s outwards thrust enabled Iranian builders to build much flatter vaulted roofs than were common in Egypt.

Roof bricks in the case of the Woodless Construction measure 200 x 150 x 60 mm, and are produce three at a time in a wooden ro meatl mould. All the bricks are laid in a mud mortar.

Adapting to local needs : changes to the vault building process.

Drawing the vault with wires

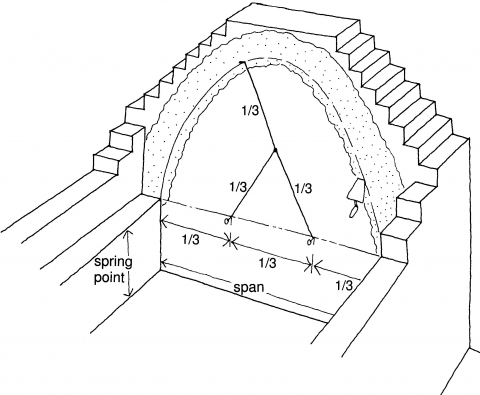

Whilst Nubian vaults were drawn by eye or with a template, Sahelian builders found drawing by eye difficult to learn and the use of a template unwieldy and impractical. A method has therefore been developed using wires and based on the subdivision of any given vault span into thirds. Based on this one-third length, three equal length wires are joined at a common point. Two nails are placed at spring point level into the end walls of vaulted rooms at one and two third intervals, to which the two of the wires are attached. The builder can quickly and accurately draw the curve of the vault. The vault shape is not only close to that of the Nubian vaults, but in addition has a more accentuated curve that compensates for the loading over the sides of vault produced by infilling the valleys in the roof. X = one third of the span

Keeping the vault shape right

Unlike Nubian vaults usually built out from one end wall, to help the Sahel builders keep a straight alignment, an early innovation has been the practice of starting a vault simultaneously from both ends of the room. Despite the strings, many builders found it difficult to keep the right curve in the lower part of the vault, leading to a much weaker vault form. To overcome this, Development Workshop changed the vault building system in late 1997, so that the builder now builds up the supporting wall with large bricks, progressively stepped out to the interior of the vaulted room. The steps follow the curve of the vault. Small vault bricks start to be laid about one third of the way up the height of the vault. Controlling the alignment of the stepped out bricks is both easy and fast, and builders unanimously prefer this new technique.

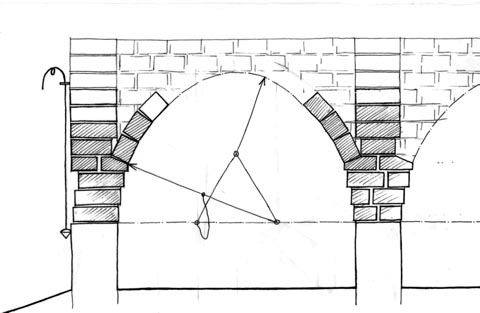

Introducing eccentric roofs

With the aim of reducing the spring point level and thus outward force on outside supporting walls, whilst gaining height on the opposite “interior” wall, “eccentricity” has been introduced as an option where the counterthrust of an adjacent roof permits. The resulting rooms have more vertical wall against which furniture can be placed, and creating openings between adjacent rooms is easier. Eccentric or off-centred vaults and domes can only be built where two roof structures provide an opposing thrust. It is equally possible to build low profile vaults where the external forces can be compensated by the opposing thrust of adjacent roofs.